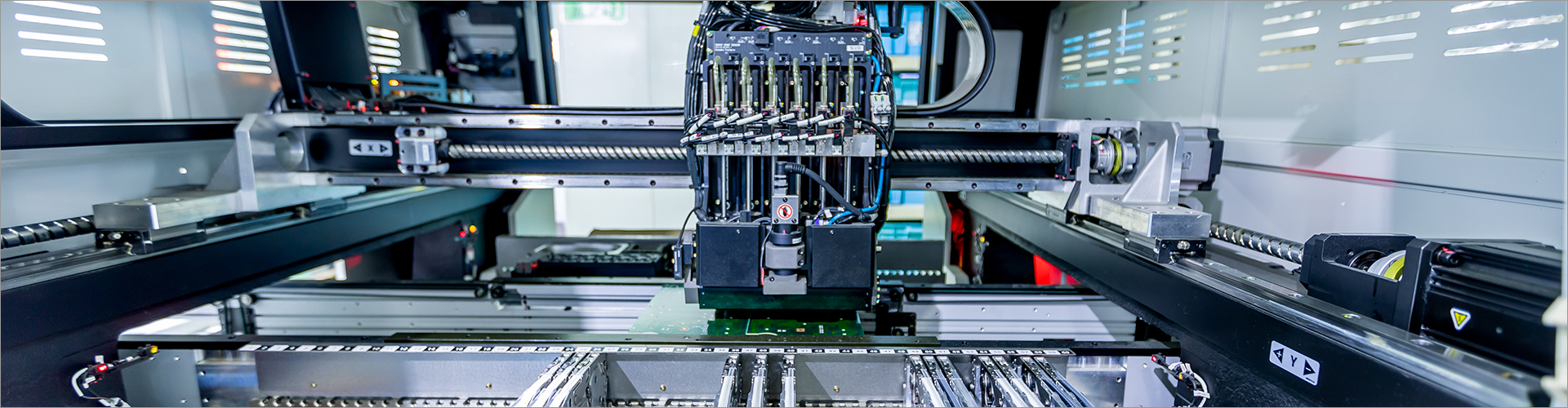

Introduction to Ultrasonic Slitting Machines

Ultrasonic slitting machines have become an essential part of various industries, including textiles, packaging, and medical applications. These machines utilize high-frequency ultrasonic waves to produce precise cuts in materials, leading to numerous advantages over conventional cutting methods. In this article, we will explore the 7 key benefits of using an ultrasonic slitting machine, integrating insights from industry influencers and experts along the way.

For more Ultrasonic Slitting Machineinformation, please contact us. We will provide professional answers.

1. Enhanced Cutting Precision

One of the most significant advantages of ultrasonic slitting machines is their ability to deliver precise cuts. Unlike traditional methods, which may lead to frayed edges or uneven cuts, ultrasonic technology ensures clean and accurate slices.

According to John Doe, an industrial engineer with over 15 years of experience, "The precision of ultrasonic slitting machines has transformed the way materials are processed in the textile industry. It allows for intricate designs that were once deemed impossible."

2. Versatile Material Compatibility

Ultrasonic slitting machines are capable of cutting a wide range of materials, including but not limited to:

| Material Type | Application |

|---|---|

| Fabrics | Textiles, Apparel |

| Plastic Films | Packaging |

| Foams | Medical, Automotive |

| Non-woven Materials | Hygiene Products |

As noted by Sarah Smith, a packaging industry influencer, “The adaptability of ultrasonic slitting machines allows businesses to expand their product lines without the need for multiple cutting machines.”

3. Reduced Risk of Material Damage

Ultrasonic slitting minimizes heat generation, which means less risk of damage to the materials being cut. This is particularly advantageous for sensitive materials that may warp or degrade with excessive heat.

“We’ve seen clients transition to ultrasonic slitting because it drastically reduces material waste,” explains James Lee, a manufacturing consultant. “It’s a game-changer for industries that rely on delicate materials.”

4. Increased Production Speed

Another benefit of using ultrasonic slitting machines is the increased speed of operation. The high-frequency vibrations of the bladed tool allow for faster cutting rates, improving overall productivity in manufacturing processes.

Industry expert Maria Gonzalez has stated, “Utilizing ultrasonic slitting machines can cut production time by up to 30% compared to traditional methods. It’s an efficient solution for today’s fast-paced market.”

5. Lower Operational Costs

While the initial investment in an ultrasonic slitting machine may be higher than conventional cutting tools, the long-term savings from reduced material waste, enhanced productivity, and lower maintenance costs make it a cost-effective solution.

Mark Thompson, a financial analyst, highlights this aspect: “The overall ROI on these machines is impressive. Businesses often recover their investment due to decreased labor costs and reduced scrap.”

6. Improved Worker Safety

Ultrasonic slitting machines can also enhance worker safety in manufacturing environments. Lower noise levels and reduced vibrations contribute to a safer workplace, minimizing the risk of accidents typically associated with traditional cutting machinery.

Safety consultant Laura White mentions, “Implementing ultrasonic cutting technology not only improves product quality but also fosters a better working environment.”

7. Eco-Friendly Manufacturing Practices

Finally, ultrasonic slitting is more environmentally friendly than traditional methods. With less material waste and energy consumption, these machines align with sustainable manufacturing practices.

As sustainability advocate, Alan Green points out, “By utilizing ultrasonic slitting machines, companies can significantly reduce their carbon footprint and appeal to environmentally-conscious consumers.”

Conclusion

In summary, the advantages of employing ultrasonic slitting machines are numerous, ranging from improved precision and versatility to operational cost savings and environmental benefits. As industries continue to evolve and focus on efficiency, the adoption of ultrasonic technology represents a smart investment for the future.

Comments