Dec. 08, 2025

Sidewall conveyor belts are designed to transport bulk materials at steep angles or even vertically—situations where traditional flat conveyor belts fail. Their unique structure makes them indispensable in space-constrained and high-capacity conveying systems.

However, because they differ significantly from standard belts, buyers and engineers often have recurring questions before selecting a sidewall conveyor belt. Understanding these concerns is key to choosing the right solution.

Below are the five questions most commonly asked when evaluating sidewall conveyor belts.

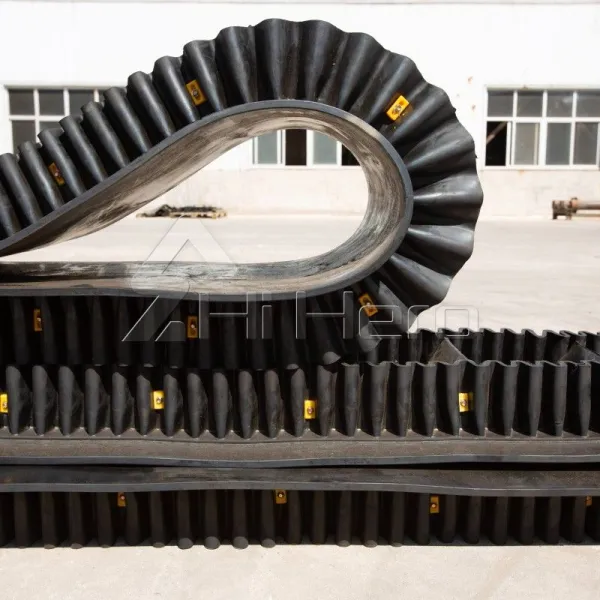

A sidewall conveyor belt consists of three main components:

Base belt (usually fabric or steel cord reinforced)

Corrugated sidewalls bonded to both edges

Cleats (cross ribs) fixed to the belt surface

The corrugated sidewalls prevent material from spilling off the sides, while the cleats carry material upward along an inclined or vertical path. Together, these features allow bulk materials to be conveyed at angles far steeper than conventional conveyor belts.

This design makes sidewall conveyor belts ideal for vertical, zigzag, or steep-angle conveying systems.

One of the biggest advantages of sidewall conveyor belts is their ability to handle extreme inclines.

Depending on belt design, sidewall height, and cleat structure, sidewall conveyor belts can operate at:

Steep inclines up to 90 degrees (vertical conveying)

Angles far beyond the 18–25° limit of standard flat belts

However, the maximum achievable incline depends on:

Material flow characteristics

Cleat spacing and height

Sidewall flexibility and bonding strength

Conveyor speed and loading method

Proper engineering is essential to ensure stable material transport without rollback or spillage.

Sidewall conveyor belts are primarily used for bulk materials that would otherwise spill on inclined conveyors.

Common materials include:

Coal, ores, and minerals

Sand, gravel, and aggregates

Fertilizers and grain

Cement, clinker, and building materials

Recyclables and industrial bulk products

Material size, moisture content, and abrasiveness all influence belt design. Sidewall height, cleat profile, and rubber compound must be selected based on actual material properties and operating conditions.

Durability is a frequent concern because sidewalls and cleats experience repeated flexing, especially around pulleys.

High-quality sidewall conveyor belts are designed with:

Strong rubber-to-fabric or rubber-to-steel bonding

Flexible but crack-resistant sidewall compounds

Reinforced cleat structures to resist fatigue and wear

When properly designed and installed, sidewalls and cleats maintain their shape and bonding strength over long service periods. Premature failure is usually caused by improper pulley design, excessive belt tension, or poor material loading practices.

Although sidewall conveyor belts have a higher initial cost than standard flat belts, they often provide significant overall cost benefits.

They can:

Replace multiple conveyors with a single steep-angle system

Reduce transfer points, spillage, and dust generation

Save valuable plant floor space

Lower structural and civil engineering costs

In many installations, sidewall conveyor belts offer a more compact, efficient, and economical solution than bucket elevators or complex multi-stage conveyor layouts.

Sidewall conveyor belts solve one of the most challenging problems in material handling: conveying bulk materials at steep angles or vertically while maintaining stability and cleanliness.

By understanding how sidewall conveyor belts work, how steep they can convey, what materials they handle best, their durability factors, and their overall cost efficiency, buyers can confidently select the right system for demanding industrial applications.

When properly designed and manufactured, sidewall conveyor belts deliver reliable performance, space savings, and long-term value in even the most challenging conveying environments.

50

0

0

All Comments (0)

Previous: Jakie są najczęstsze problemy z ładowarką PCB SMT?

Next: سماعة تفريغ لوحة الدوائر المطبوعة تلقائية SMT من هياوي: الحل لبوردات الدوائر المثالية

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments